I/O-Modules

Fox Series

Lightbus - Coupler

The

TRS Fiber Optic Industrial Input/Output System, which is referred to as

the FO-II/O system to save space, consists of an intelligent central

module and an optical waveguide-based field bus. The TR-Fieldbus Systems

Industrial Input/Output System is a universal input/output system for

industrial control technology.

Depending

on the system (PC/AT, SMP, AMS, AT96, VME, SIMATIC, Mitsubishi etc.), the

link between the FO-II/O system and the host is implemented by means of a

Logic Cell Array. This guarantees fast, convenient communications. Various

FO-II/O peripheral modules are available for processing the process image.

These modules are connected together in a ring structure.

By

contrast with other types of communication, which are based on

handshaking, in a fiber optic ring only the central unit is active and the

other input and output modules that are connected in the ring are passive.

This makes possible rapid data communication with these modules.

Data

transfer on the optical waveguide is specified by a communications

protocol that is optimized for speed and simplicity. This type of

communication means that the message that the central unit transmits is

received by each module, which interprets it and passes it on with a delay

of approximately 1.5 µs. With a wavelength of 660 nm, the fiber

optic-bus achieves a maximum transfer rate of 6 Mbps. The system that

TRS Fieldbus Systems uses has a transfer rate of 2.5 Mbps; in this

connection, the entire transfer time of 25 µs is needed for one

32-bit message. This means that with a central unit connected to ten

modules, the system triggers and updates all the modules in approximately

300 µs. The central module detects any faults that may occur in the

fiber optic ring and reports them to the host system. The implemented ring

diagnostics functions then make possible rapid troubleshooting and removal

of faults.

The

central module controls communication in the fiber optic ring. It

transmits messages that run through the individual modules in the fiber

optic ring and finally receives them again and checks them.

The use of optical waveguides provides significant advantages compared with conventional copper cabling:

-

High transfer capacity

-

Low signal attenuation

-

No electromagnetic disturbances

-

Potential freedom

-

Low weight

Fox-10

Fox-10

Base Module fitted with three Input and one Output Submodules

The

Fox-10 is a cost effective input/output module. It fits only digital input

/ output submodule. This is most times used if you need 32 or less I/O

points.

| Submodules | Description | Slot 1 | Slot 2 | Slot 3 | Slot 4 |

| MDI-8 | 8 digital inputs | Yes | Yes | Yes | Yes |

| MDO-8 | 8 digital outputs, 24V/0.5 A | Yes | Yes | Yes | Yes |

| MDM-8 | 8 digital outputs, 24V/2.0 A | Yes | Yes | Yes | Yes |

| MAC-8 | 8 digital inputs, 110/220 V AC | Yes | Yes | Yes | Yes |

| MDR-8 | 8 relays | Yes | Yes | Yes | Yes |

| MDIO-16 Out | 16 digital outputs | No | No | No | No |

| MDIO-16 In | 16 digital inputs | No | No | No | No |

| MDIO-16 8I/8O | 8 digital inputs and 8 digtial outputs | No | No | No | No |

| MAI-4 | 4 analog inputs, resolution: 12/16 bits | No | No | No | No |

| MAO-4 | 4 analog outputs, resolution: 16 bits | No | No | No | No |

| MSSI-2 | 2 synchronous serial interfaces | No | No | No | No |

| MINC-2 | 2 incremental encoders | No | No | No | No |

| MHAS-2 | 2 HAS encoders | No | No | No | No |

| MPWM-2 | 2 pulse width modulation outputs, 24V/2.0A | No | No | No | No |

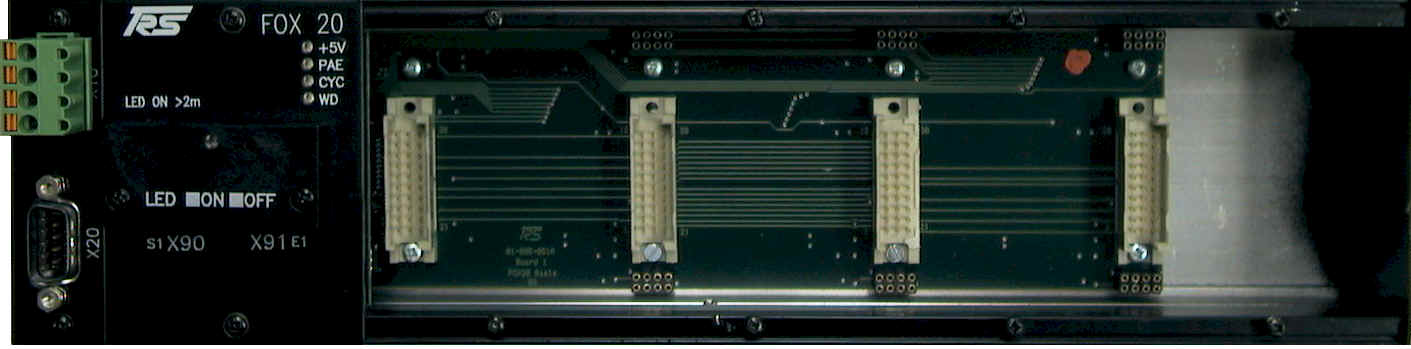

Fox-20

Base Module with one analog input, one analog output,

one digital input and one digital output submodule

The Fox-20 base module is used if you have a high density of digital I/O points (up to 64), any analog, any position or pulse with modulation submodules.

| Submodules | Description | Slot 1 | Slot 2 | Slot 3 | Slot 4 |

| MDI-8 | 8 digital inputs | No | Yes | Yes | Yes |

| MDO-8 | 8 digital outputs, 24V/0.5 A | No | Yes | Yes | Yes |

| MDM-8 | 8 digital outputs, 24V/2.0 A | No | Yes | Yes | Yes |

| MAC-8 | 8 digital inputs, 110/220 V AC | No | Yes | Yes | Yes |

| MDR-8 | 8 relays | No | Yes | Yes | Yes |

| MDIO-16 Out | 16 digital outputs | Yes | Yes | Yes | Yes |

| MDIO-16 In | 16 digital inputs | Yes | Yes | Yes | Yes |

| MDIO-16 8I/8O | 8 digital inputs and 8 digtial outputs | Yes | Yes | Yes | Yes |

| MAI-4 | 4 analog inputs, resolution: 12/16 bits | Yes | Yes | Yes | Yes |

| MAO-4 | 4 analog outputs, resolution: 16 bits | Yes | Yes | Yes | Yes |

| MSSI-2 | 2 synchronous serial interfaces | Yes | Yes | Yes | Yes |

| MINC-2 | 2 incremental encoders | Yes | Yes | Yes | Yes |

| MHAS-2 | 2 HAS encoders | Yes | Yes | Yes | Yes |

| MPWM-2 | 2 pulse width modulation outputs, 24V/2.0A | Yes | Yes | Yes | Yes |

Power Supply

You connect the power supply for the control logic via the four pin connector terminal X10 on the upper left side of the module.

Connector X10:

| Pin | Signal | Description |

| 1 | +24 V logic | Control voltage supply |

| 2 | GND logic | Ground of logic |

| 3 | +24 V logic | Control voltage supply |

| 4 | GND logic | Ground of logic |

Connector X90 / X91:

| Pin | Signal | Description |

| X90 | FO-OUT | Fiber optic ring OUTPUT |

| X91 | FO-IN | Fiber optic ring INPUT |

Three LEDs provide information about the status of the module:

Power LED Base Module (+5V only Fox-20)

| LED | Description |

| OFF | No Power, check Power at X10 connector |

| Orange | Power On |

Error LED (Error (Fox-10) or (PAE) Fox-20)

| LED | Description |

| OFF |

Messages OK (No Error) |

| Red |

Faulty messages, ckeck cable |

Cycle LED (CYC)

| LED | Description |

| OFF | No messages are send, check master |

| Green | Shows message traffic |

Watchdog

| LED | Description |

| OFF | The module receives no write message |

| Light Green | Watchdog is triggered on each output message |

You mount the DeviceNet base module off-center of the machine or in control cabinet by simply fastening it to a device mounting DIN rail.

Setting the Transmission Power

In the LED connection cap, there is a rotary switch that you can turn from outside using a small screwdriver. A green LED shows the switch setting: if the LED is lit up, the transmission power is set to 10 m .. 45 m with plastic cable or 60 ..300m with glass fiber cble; otherwise, the system runs at a power reduced by 4 dB with fiber optic cable lengths of 0.2 m .. 15 m.

Technical

Data

| Inputs/Outputs |

Max. of 32 digital

I/Os or max. of 16 analog I/Os, or a mixture of both via up to

four galvanically decoupled submodules. |

|

Input Specifications |

Refer to input modules for FOX-10/FOX-20 |

|

Output

Specifications |

Refer to output modules for FOX-10/FOX-20 |

|

Output Monitoring |

Watchdog circuit |

| Connections | Toshiba PCS Fiber Optic System or APS Fiber |

|

Data Connection |

Fiber Optic Ring II/O System |

| Transfer Rate | 2.5 Mbps, 25 µs for 32 bits |

|

Supply Voltage |

24 VDC (±

20%) |

|

Current Consumption |

approx. 0.1 A

(without submodules) |

|

Housing |

closed, can be screw-mounted on a device mounting rail complying with DIN EN 50022, 50035 |

|

Dimensions (W x H x

D) |

FOX-10:

305 * 76 * 68 mm FOX-20: 315 * 76 * 68 mm |

|

Weight |

approx.. 750 g |

|

Operating

Temperature |

±0..+55 °C |

|

Storage Temperature |

-20..+70 °C |

Two base types of

fiber optic cable are available, i.e. all plastic fiber, APF and plastic

cladding silica fiber, PCS. You can lay both types on a trailing cable

chain, since the varying load meets the requirements. The fiber optic

cable transmission and reception chips are designed for APF as well as PCS

cables. APF cables guarantee safe data transmission up to 45 meters; with

PCS cables, this distance is 300 meters. Using special transmission chips

with PCS cables, you can achieve distances of up to 1000 meters.

PCS cables need different connectors from APF cables, however the II/O modules are identical (up to 300 meters). In addition, you need special tools for PCS cables.

You can use a

measuring instrument to measure the attenuation of the cable or of the

connector.

The II/O modules

are connected to the bus link via fiber optic plug-in connectors X90 and

X91 as shown in figure 2.

Preparing

the Fiber Optic Connector

It is quite easy to

prepare the fiber optic connector on the APF cable. First of all, you

strip about 25 mm of the 6-mm polyurethane jacket and cut off the Kevlar

strain relief appropriately without damaging the black internal sheath.

After this, strip 7 mm of the black internal sheath using a cable stripper

or a special cable-stripping tool. Under no circumstances must you damage

the transparent fiber while doing this. Ensure that the cut surface of the

fiber does not split. By feeding in red light at the other end of the

fiber, you can check the end of the fiber. You then push the fiber from

the back all the way in to the connector and then push in the clamping

fixture in to the connector using a screwdriver or similar tool. After

this, sand the end of the fiber that is sticking out of the connector at

right angles to the connector; to do this, first use 600 grain and then

1000 grain emery paper. You must not sand the connector itself. Do not use

any chemical-based polishing pastes, as they harden the fiber. It is

sensible to use a magnifying glass to check the results.

back | Fox Series | Download | Home

Copyright © 2000 TRS

Fieldbus Systems, Inc. All rights reserved.

Revised: August 08, 2000

.